Projects

10 Best Online Metal Fabrication Services for Your Project Needs?

In today's rapidly evolving manufacturing landscape, online metal fabrication has become a vital resource for many industries. According to John Smith, a leading expert in the field of online metal fabrication, “The future of fabrication is digital, making it more accessible for small businesses and startups.” This transition allows fabricators to meet diverse project needs more efficiently.

Online metal fabrication services offer customizable solutions that cater to specific project requirements. Customers can choose materials, sizes, and designs with just a few clicks. This flexibility helps businesses save time and costs. Yet, not all services provide the same quality. It’s crucial to research and compare options to find a reliable partner.

Some users may encounter difficulties with communication or delivery timelines. These can lead to frustration and delays in projects. A clear understanding of expectations from both parties is key. By selecting the right service, you can harness the advantages of online metal fabrication effectively, turning ideas into tangible products.

Overview of Online Metal Fabrication Services

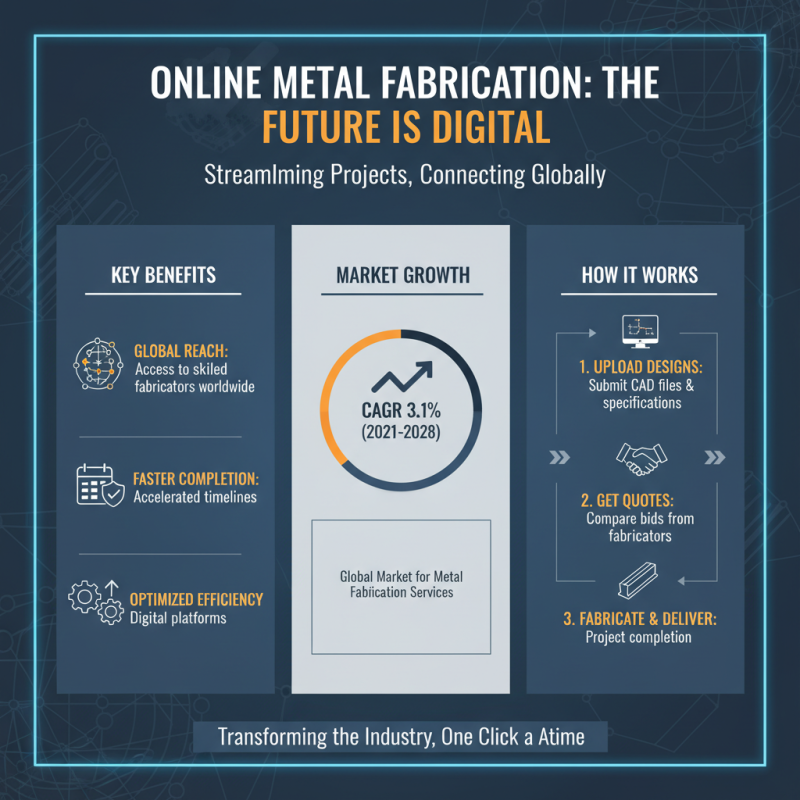

Online metal fabrication services are transforming the way projects get completed. The convenience of digital platforms allows businesses to connect with skilled fabricators worldwide. In fact, the global market for metal fabrication services is expected to grow at a compound annual growth rate (CAGR) of around 3.1% between 2021 and 2028.

These services offer various techniques, from laser cutting to welding, catering to different project needs. A 2022 report indicated that nearly 70% of projects are completed faster with online services. However, quality control remains a challenge. Projects often face setbacks due to miscommunication or material defects. It's crucial to assess the capabilities and reviews of each service thoroughly.

Innovation is key in this field. A recent study showed that 55% of fabricators are investing in automation and advanced technologies. Yet, dependence on technology can create gaps in craftsmanship. Many projects still require a human touch. As industries evolve, so must the standards in metal fabrication. Balancing speed, quality, and innovation is essential for success.

Key Factors to Consider When Choosing a Service

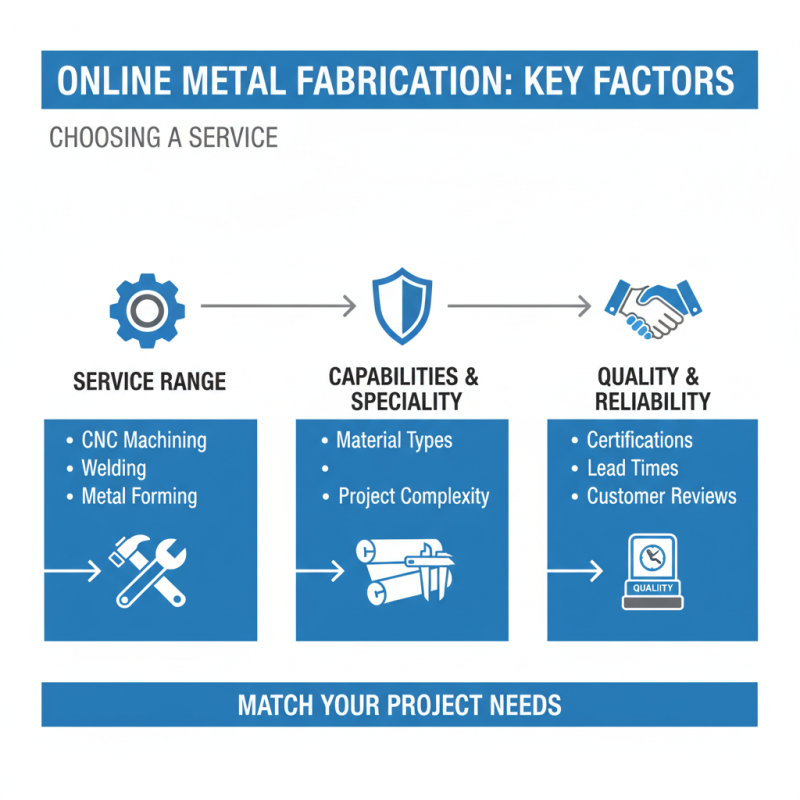

When selecting an online metal fabrication service, consider several key factors. Quality is crucial. Examine the materials they use. Low-quality metals can lead to structural issues. Look for services that openly share their quality control process. Certifications can indicate reliability and expertise.

Communication matters greatly. A responsive team can streamline your project. Check if they offer design support. Sometimes, your vision needs tweaks. Clear and timely feedback improves the outcome. Poor communication often leads to delays and frustration.

Tip: Always ask for samples before committing. It helps in assessing quality firsthand. Understand their turnaround times too. Some services may promise quick delivery but lack consistency. Reliability is as important as quality in metal fabrication.

Reviews of the Top 10 Online Metal Fabrication Providers

When choosing an online metal fabrication service, it’s crucial to consider several factors. First, look for providers that offer a range of services. Some focus solely on CNC machining, while others may handle welding and metal forming. Understanding their specialties can help match their offerings to your project needs.

Tips: Always check their portfolio. A strong history of diverse projects can indicate reliability. Look for customer reviews and testimonials for insights into their work quality. Communication is key too. Ensure the provider is responsive, as this can impact the project's timeline.

Also, consider the materials they work with. Different providers specialize in specific metals, like aluminum or stainless steel. Verify they can handle your required specifications. It’s frustrating to realize, after the fact, that a chosen provider lacks the capability you need.

Remember, not every provider will meet your expectations. Some may have long turnaround times or hidden fees. Be prepared to ask questions and seek clarifications. Transparency in prices often reflects a company’s integrity. Prioritize clarity to avoid surprises down the line.

Comparison of Pricing and Features Among Services

Finding the right online metal fabrication service can be overwhelming. Many options vary significantly in pricing and features. This makes it essential to evaluate each service thoroughly. Start by considering the material types they offer. Some services excel in stainless steel, while others focus on aluminum.

Pricing structures are another key aspect. Some platforms charge per hour of machining, while others offer fixed rates for specific services. Be mindful of hidden fees that might surface later in the process. Sometimes, a lower initial price does not reflect the overall cost. Reviews can help clarify the quality of service, but they can also be subjective.

Features like customer support matter too. Fast response times can make a big difference. Not every service provides live chat or instant quotes, which can frustrate users. Some platforms lack clear communication channels, leading to delays. Comparing these elements lets you see where each service falls short. This will guide you to a better-informed choice.

Comparison of Online Metal Fabrication Services

Tips for Effective Communication with Metal Fabrication Companies

Effective communication with metal fabrication companies can greatly enhance project outcomes. Clear discussions about project specifications are crucial. According to a report from the Fabricators and Manufacturers Association, 70% of project delays stem from misunderstandings. Provide detailed project requirements. Include dimensions, materials, and finishes.

Visual aids, like sketches or diagrams, can clarify your ideas. Prepare to discuss timelines and budgets openly. Industry data shows that 60% of projects exceed initial budget estimates due to vague costing. Ask for itemized quotes to ensure transparency. A simple email can clarify complex questions. Use direct language and be specific about your needs.

Listening is just as important as conveying your thoughts. Occasionally, what you assume is understood might not be. Engaging in an open dialogue can reveal new insights. Be receptive to feedback from fabrication experts. They can offer valuable suggestions to improve your design. Recognizing areas where your specifications may fall short can lead to better results. Take the time to collaborate effectively.

Related Posts

-

2026 Top Trends in Custom Metal Fabrication You Need to Know

-

How to Choose Custom Metal Fabrication Services for Your Project?

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

Why Welding and Fabrication Skills Are Essential for Modern Industries

-

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

-

10 Essential Tips for Successful Online Fabrication Projects