Projects

10 Best Tube Fabrication Techniques for Optimal Performance

In the dynamic world of manufacturing, tube fabrication stands out as a critical process that significantly influences the quality and efficiency of final products. Experts in the field emphasize the importance of employing the best techniques to maximize performance. As noted by John Smith, a leading authority in tube fabrication, "The precision and care taken during the fabrication process can make or break a project." This sentiment underscores the need for industry professionals to stay updated on innovative practices and methodologies that enhance tube design and durability.

The landscape of tube fabrication has evolved dramatically over the years, with advancements in technology and materials driving new techniques. From welding and bending to cutting and finishing, each step in the fabrication process requires a level of expertise that only a well-educated workforce can deliver. Consequently, understanding and implementing the ten best tube fabrication techniques not only optimizes performance but also reduces waste and increases overall efficiency.

As the industry continues to grow, it is essential for manufacturers to keep pace with emerging trends and refine their skills. By exploring innovative tube fabrication methods, companies can ensure they remain competitive and capable of delivering high-quality products to meet the demands of an ever-changing market.

Best Tube Fabrication Techniques for Enhancing Structural Integrity

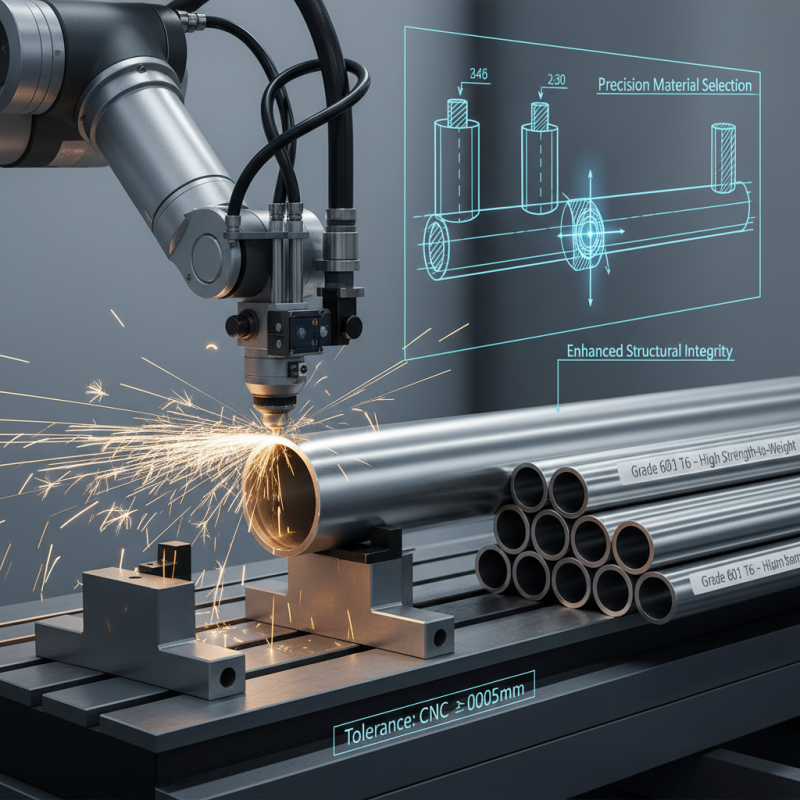

When it comes to enhancing structural integrity in tube fabrication, several techniques stand out for their effectiveness. One of the foremost methods is precise material selection, where using high-quality, grade-appropriate metals can significantly impact a structure's performance. Stainless steel and aluminum, for instance, offer excellent strength-to-weight ratios, making them ideal for components that demand resilience while minimizing excess weight. Employing advanced Computer Numerical Control (CNC) machining helps in achieving precise tolerances during the cutting and shaping of tubes, ensuring a perfect fit without compromising durability.

Moreover, incorporating techniques such as welding and heat treatment can further bolster a tube’s structural integrity. Proper welding methods, including TIG and MIG, provide strong joints that can withstand significant stresses. After welding, employing heat treatment processes can relieve internal stresses and improve mechanical properties. The combination of these fabrication techniques not only enhances the structural performance of tubes but also extends their lifespan, making them suitable for various demanding applications across industries. By prioritizing these best practices, engineers can significantly improve the reliability and efficiency of tube-based structures.

The Role of Material Selection in Tube Fabrication Efficiency

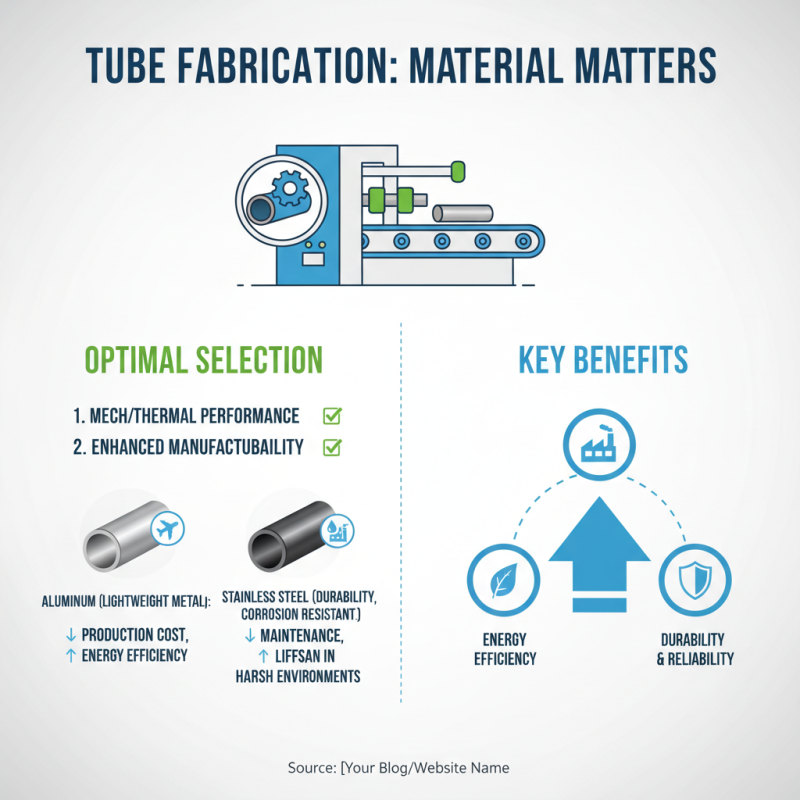

The efficiency of tube fabrication heavily relies on the selection of materials used in the process. It is crucial to choose materials that not only meet the mechanical and thermal performance requirements but also enhance manufacturability. For example, lightweight metals like aluminum can reduce production costs and improve energy efficiency in applications where weight is a concern. Similarly, materials like stainless steel offer durability and resistance to corrosion, making them ideal for applications in harsh environments, thus reducing maintenance and replacement frequency.

Moreover, the proper material selection can significantly influence the fabrication techniques employed. Techniques such as bending, welding, or cutting may perform differently depending on the material's properties. For instance, ductile materials allow for smoother bending without cracking, while harder materials may require specialized cutting tools. By understanding the interactions between material properties and fabrication techniques, manufacturers can optimize their processes, achieving better quality products with increased efficiency and reduced waste. This strategic alignment between material selection and fabrication methods plays a pivotal role in enhancing the overall performance of tube fabrication operations.

Advanced Welding Methods for Superior Tube Joint Strength

When it comes to tube fabrication, achieving superior joint strength is crucial for optimal performance in various applications, from automotive to aerospace. Advanced welding methods are at the forefront of this enhancement, with techniques like laser welding and friction stir welding gaining popularity in the industry. According to a report by the American Welding Society, laser welding can improve joint strength by up to 30% compared to conventional methods due to its minimal heat input and precise control over the weld area, significantly reducing distortion and defects.

Friction stir welding, on the other hand, offers unique advantages for aluminum and other non-ferrous materials, often resulting in joints that do not require filler material and maintaining the material’s base properties. The Friction Stir Welding Consortium reported that this method can enhance fatigue resistance by approximately 40%, making it particularly valuable in applications demanding high durability and resilience. By implementing such advanced techniques, manufacturers can improve the reliability and performance of their tube assemblies, thereby meeting the increasing demands of modern engineering challenges.

10 Best Tube Fabrication Techniques for Optimal Performance

This chart illustrates the strength ratings of various tube fabrication techniques, showcasing their effectiveness in optimal performance for tube joints. Each method is rated from 1 to 10, indicating its strength and reliability in fabrication.

Optimizing Tube Design for Reduced Weight and Increased Durability

In the realm of tube fabrication, optimizing tube design is paramount for achieving reduced weight without compromising durability. A key technique is the use of advanced materials, such as high-strength alloys and composite materials, which offer significant strength-to-weight ratios. By selecting lightweight materials and employing innovative manufacturing processes, engineers can design tubes that are not only lighter but also maintain structural integrity under stress. For instance, utilizing finite element analysis during the design phase allows for the identification of stress concentration areas, enabling targeted reinforcement while minimizing excess material.

Furthermore, advanced fabrication techniques such as hydroforming and laser cutting can contribute to enhanced performance. Hydroforming allows for complex shapes to be created from tubes, which can improve both aerodynamic efficiency and strength. Meanwhile, precision laser cutting ensures that the material is used effectively, reducing waste and promoting an overall lighter design. Combining these methods leads to a holistic approach in tube fabrication, where each design decision directly contributes to both weight reduction and an increase in durability, ultimately leading to superior product performance in various applications.

Utilizing CNC Technology in Precision Tube Fabrication Processes

In the modern landscape of tube fabrication, CNC technology has revolutionized precision processes, enhancing both efficiency and accuracy. According to a report by MarketsandMarket, the CNC machining market is projected to reach $100 billion by 2025, emphasizing the rising importance of automation and precision in manufacturing. By integrating CNC systems, fabricators can achieve tight tolerances and complex geometries that were previously unattainable with traditional methods, ensuring optimal performance in final products.

One crucial advantage of CNC technology is its ability to streamline processes. Automated setups reduce human error and increase repeatability, critical aspects in industries requiring stringent specifications, like aerospace and medical device manufacturing. Data from the International Journal of Advanced Manufacturing Technology reveals that CNC machines can improve production efficiency by up to 60%, allowing businesses to meet high demand with consistent quality.

Tips: To maximize the benefits of CNC technology in your tube fabrication process, invest in training for your operators on advanced programming techniques. Additionally, implement regular maintenance schedules for your CNC machines to ensure optimal performance and reduce downtime. Embracing these practices can significantly elevate your production capabilities and product quality.