Projects

How to Choose Custom Metal Fabrication Services for Your Project?

Choosing the right custom metal fabrication service can be challenging. Many factors must be considered. Each project has unique needs. It's essential to find a company that understands your requirements.

Look for experience in the industry. A reputable fabricator should have a strong portfolio. Check their previous work to gauge their skills. Quality is crucial. The materials used must meet high standards. Poor choices can lead to project delays or structural failures.

Communication matters, too. Ensure they listen to your ideas and feedback. Misunderstandings can cause issues later. Reflect on their customer service. Are they responsive and open to questions? Taking the time to choose wisely will lead to better results. A successful project relies on the right partnership in custom metal fabrication.

Understanding Your Project Requirements for Metal Fabrication

Understanding project requirements is vital for effective metal fabrication. A clear outline of what you need can prevent costly mistakes down the line. In fact, around 70% of metal fabrication failures are attributed to unclear specifications. Knowing your project's unique demands helps you communicate better with fabricators.

Consider the material type and thickness you require. Different metals have distinct properties that affect final performance. For example, aluminum is lightweight but less strong than steel. If your project requires high strength, opting for stainless steel may be wise. Also, think about dimensions and tolerances. Do you need precise cuts or custom shapes? This level of detail can impact fabrication costs significantly.

You should also reflect on your time frame. Rushing a project could increase errors and lead to poor quality. Many metal fabricators report that tight schedules can compromise their ability to deliver precision work. Lastly, assessing your budget is key. Sometimes, cheaper options may end up costing more due to lower quality. Balancing cost and quality should be a core consideration as you move forward with your project.

Evaluating the Expertise and Capabilities of Fabrication Services

When selecting custom metal fabrication services, evaluating expertise is crucial. Look for providers with a solid track record. A good history indicates reliability and skill. Ask for examples of past projects. Check if they align with your needs. This can give insight into their capabilities.

Consider the range of services offered. Some companies excel in specific areas, while others provide a wider range. It's important to find a balance. Specialized skills might come with higher quality but at a steeper price. Look for flexibility in manufacturing techniques. Can they handle prototyping as well as large-scale production?

Communication matters too. A responsive team can streamline your project. If initial communication is poor, it might reflect future interactions. Ask questions about their processes. Understanding how they operate can reveal their level of professionalism. Sometimes, flaws in their approach can be a red flag. Trust your instincts when evaluating these aspects.

How to Choose Custom Metal Fabrication Services for Your Project? - Evaluating the Expertise and Capabilities of Fabrication Services

| Criteria | Description | Importance Level |

|---|---|---|

| Experience | Years of experience in metal fabrication and specific industries. | High |

| Capabilities | Range of services offered, including cutting, welding, and finishing. | High |

| Quality Control | Measures in place to ensure the quality of fabrication. | High |

| Equipment | Type and condition of machinery used in fabrication process. | Medium |

| Customer Service | Responsiveness and support provided to clients during projects. | Medium |

| Certifications | Relevant industry certifications that indicate quality standards. | Low |

| Location | Proximity to your site for easier logistics and communication. | Low |

Comparing Material Types and Their Suitability for Your Project

When selecting custom metal fabrication services, understanding material types is crucial. Various metals offer distinct properties that impact performance and suitability. For instance, aluminum is lightweight and resistant to corrosion, making it ideal for aerospace applications. In contrast, steel is stronger and provides excellent tensile strength, preferred for structural engineering.

According to the "Metal Fabrication Market Analysis," 30% of industry professionals cite steel as their material of choice due to its versatility. However, aluminum's lightweight nature can lead to reduced fuel costs in transportation sectors, reflecting a growing trend. Copper also has significant electrical conductivity, vital for electronics. Yet, its cost may deter some designers.

The choice between these metals often involves trade-offs. Steel's durability can compromise weight advantages, while aluminum may not handle heavy loads as effectively. Additionally, environmental considerations come into play, as the production of certain metals can generate significant waste. Balancing these factors is essential for project success. Each metal type has strengths and limitations, urging careful evaluation based on project requirements.

Analyzing Cost Estimates and Budget Constraints Effectively

When selecting a custom metal fabrication service, analyzing cost estimates is crucial. According to recent industry reports, labor costs can account for 30-50% of the total project budget. Material prices fluctuate significantly, influenced by global demand. Therefore, staying informed about market trends is essential.

One effective way to manage your budget is to obtain multiple quotes. This practice can reveal substantial price variations. Sometimes, a lower quote may compromise quality. Assess each estimate carefully. Hidden charges can inflate costs later.

Tip: Always ask about material sources. Recycled metals might save costs while reducing waste. Quality deserves attention, but cost is a reality. Inadequate budget planning can lead to project delays or adjustments. Assess your priorities for both quality and price accurately.

Another area to consider is the timeline. Expedite projects often incur higher costs. Compare timelines in quotes and ask about their impact on pricing. Delays can affect not just money but also the project’s overall success. Balancing speed and cost is complex and requires reflection.

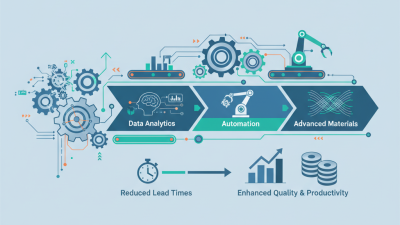

Assessing Lead Times and Delivery Options in Custom Fabrication Services

When selecting custom metal fabrication services, lead times and delivery options are critical. Understanding these factors can significantly impact project timelines. Some companies offer quick turnaround, while others may have long waiting periods. It's essential to ask for estimated delivery dates upfront. This helps in planning and ensures the entire project remains on schedule.

In addition to lead times, explore the delivery options available. Some services may provide local delivery, while others may ship nationwide. Confirm the logistics before deciding. Unexpected delays in shipping can derail everything. Don't hesitate to inquire about potential bottlenecks. At times, issues arise that might not be immediately obvious, like supply chain constraints. Keep communication open to avoid misalignments later on. Remember, a transparent provider builds trust, but if they fail to communicate, it could lead to frustrations. Always reflect on these aspects before making a final choice.

Lead Times and Delivery Options in Custom Metal Fabrication Services

Related Posts

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

2026 Top Trends in Custom Metal Fabrication You Need to Know

-

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

-

10 Essential Tips for Successful Online Fabrication Projects

-

How to Efficiently Optimize Part Fabrication Processes for Better Productivity

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget