Projects

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know

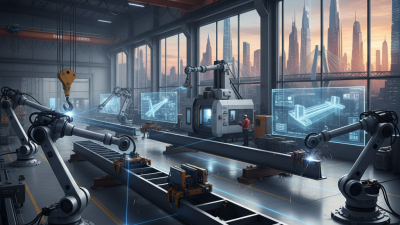

In the ever-evolving landscape of manufacturing, custom steel fabrication stands at the forefront of industrial innovation. As we approach 2025, it is essential to recognize the pivotal trends shaping this sector and their implications for businesses and consumers alike. Custom steel fabrication is not merely about producing steel structures; it encompasses a dynamic approach that leverages advanced technologies, sustainability practices, and bespoke solutions tailored to meet specific project requirements.

As industries continue to demand higher levels of customization and efficiency, the trends emerging in custom steel fabrication highlight the growing emphasis on automation, digitalization, and eco-friendly practices. Innovations such as 3D printing, robotics, and real-time monitoring are transforming traditional fabrication methods, enabling companies to deliver superior quality and reduce lead times significantly. Furthermore, the increasing awareness of environmental impacts is driving the adoption of sustainable materials and processes, making custom steel fabrication not only more efficient but also more responsible.

Understanding these trends will be crucial for stakeholders looking to navigate the future of custom steel fabrication. By staying informed and adaptable, businesses can harness the opportunities presented by these advancements, ensuring they remain competitive in a rapidly changing market. As we delve deeper into the key trends to watch in 2025, it becomes clear that the future of custom steel fabrication is bright, innovative, and filled with potential.

Emerging Technologies in Steel Fabrication for 2025

As we move towards 2025, the steel fabrication industry is set to undergo significant transformations driven by emerging technologies. One of the most noteworthy trends is the integration of automation and robotics in fabrication processes. These technologies not only enhance precision and efficiency but also minimize human error, leading to safer work environments and faster production cycles. Automated systems can handle repetitive tasks, allowing skilled workers to focus on more complex, value-added activities that require creative solutions.

Another crucial development is the adoption of advanced materials and techniques. Additive manufacturing, also known as 3D printing, is poised to revolutionize how metal components are produced. This technology enables the creation of intricate designs that were previously impossible with traditional methods, leading to lighter and stronger parts. Additionally, smart technologies such as IoT (Internet of Things) are beginning to play a significant role in steel fabrication. They allow for real-time monitoring and data analysis, facilitating better decision-making and predictive maintenance that can enhance overall productivity and reduce operational costs.

These emerging technologies not only promise to increase efficiency and innovation in the steel fabrication industry but also lay the groundwork for sustainable practices. As demands for eco-friendly solutions rise, the industry is likely to turn towards greener technologies, optimizing resource usage and minimizing waste while producing high-quality steel products. The convergence of these technological advancements will undoubtedly shape the future landscape of steel fabrication.

| Trend | Description | Expected Impact | Technologies Involved |

|---|---|---|---|

| Automation and Robotics | Increased integration of automated systems to enhance precision and speed in fabrication processes. | Higher efficiency and lower labor costs. | Robots, AI-driven software |

| Sustainable Practices | Adopting environmental-friendly materials and processes to minimize waste. | Improved company reputation and compliance with regulations. | Recycling technologies, energy-efficient systems |

| 3D Printing | Utilization of 3D printing technology for custom steel components. | Reduced production times and complexity of designs. | Metal 3D printers, CAD software |

| Predictive Analytics | Use of data analytics to anticipate maintenance needs and optimize production schedules. | Reduced downtime and operational costs. | Big data, IoT sensors |

| Augmented Reality (AR) | Using AR for design visualization and training employees on complex tasks. | Enhanced training efficiency and design validation. | AR glasses, VR training modules |

Sustainability Practices Impacting Steel Fabrication Trends

As we approach 2025, sustainability practices are increasingly defining the landscape of custom steel fabrication. The push for eco-friendly manufacturing processes is not just a trend but a necessity driven by regulatory pressures and customer demand for greener options. Steel fabricators are focusing on reducing their carbon footprint through innovative techniques such as using recycled materials and employing energy-efficient machinery. This commitment to sustainability is reshaping production methods, leading to a more environmentally responsible industry.

Moreover, the integration of advanced technologies, such as automation and data analytics, is helping steel fabricators optimize their processes while minimizing waste. These technologies allow for precise measurements and enhanced quality control, reducing material surplus and ensuring that every piece of steel is utilized effectively. By adopting lean manufacturing principles, companies can significantly lower their environmental impact while maintaining profitability. As the industry continues to evolve, those who prioritize sustainability will not only meet compliance goals but also attract a more conscious consumer base.

Steel Fabrication Trends in 2025

This chart illustrates the anticipated impact of key trends in steel fabrication by 2025, focusing on sustainability practices, automation, customization, quality control, and supply chain resilience. Each trend is rated on a scale from 1 to 10, indicating its expected significance in the industry.

Customization and Personalization in Steel Products

In recent years, the demand for customization and personalization in steel products has gained significant momentum, driven by the evolving needs of industries ranging from construction to automotive. According to a report by the Fabricators and Manufacturers Association (FMA), 63% of manufacturers are prioritizing custom solutions to meet the specific requirements of their clients, highlighting a clear shift toward tailored fabrication processes. This trend is particularly evident in projects where unique specifications are critical to achieving performance and design goals.

As we look ahead to 2025, the integration of advanced technologies such as 3D printing and automated cutting systems is set to enhance the customization capabilities of steel fabrication. The International Steel Association predicts that 45% of all steel products will feature some level of customization, a monumental increase from the current rates. This allows fabricators to provide bespoke solutions that cater to individual project specifications, thus improving product efficiency and satisfying clientele needs. Industries embracing these custom solutions are likely to witness increased profitability and improved client retention rates, as the focus on personalized service becomes imperative in a competitive marketplace.

The Role of Automation in Modern Steel Fabrication

Automation is set to revolutionize the steel fabrication industry in 2025, bringing efficiency and precision to the manufacturing process. The integration of advanced robotics, artificial intelligence, and machine learning into fabrication workflows allows companies to streamline operations, reduce labor costs, and minimize human error. Automated systems can handle intricate cutting, welding, and assembling tasks with unmatched accuracy, resulting in higher quality products and faster turnaround times.

Moreover, the role of automation extends beyond just physical tasks; it also encompasses data management and predictive analytics. By utilizing IoT devices and sensors across the production line, manufacturers can collect real-time data to monitor equipment performance and predict maintenance needs, thereby preventing costly downtimes. This data-driven approach enables companies to optimize their operations, make informed decisions, and respond quickly to market demands, ultimately driving growth and innovation in the steel fabrication sector.

Market Demand Shifts and Their Influence on Steel Manufacturing

As we approach 2025, the custom steel fabrication sector is witnessing significant shifts in market demand influenced by various factors, including technological advancements and sustainability concerns. A recent report by the World Steel Association highlights that the global demand for steel is expected to increase by approximately 1.3% annually, driven by infrastructure projects and the growth of renewable energy sectors. The rising emphasis on sustainable practices is prompting manufacturers to rethink their processes, leading to an increased demand for eco-friendly materials and energy-efficient manufacturing techniques.

Furthermore, the integration of automation and advanced robotics in steel fabrication is reshaping operational capabilities. According to a study published by McKinsey & Company, the adoption of digital technologies in the manufacturing sector has the potential to improve productivity by up to 30%. This trend is becoming more pronounced in steel fabrication, where companies are leveraging automation to meet the growing demand for custom products while minimizing waste. As customers increasingly seek tailored solutions, fabrication firms are investing in flexible manufacturing systems that can quickly adapt to changing specifications without sacrificing quality or efficiency. This adaptability is crucial in a market characterized by rapid innovation and shifting consumer preferences.

Related Posts

-

2025 Top Steel Beam Fabrication Techniques for Modern Construction

-

What is Stainless Fabrication Its Process Benefits and Applications

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

How to Master Welding and Fabrication Techniques for Successful Projects

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget