Projects

How to Efficiently Optimize Part Fabrication Processes for Better Productivity

In the ever-evolving landscape of manufacturing, optimizing part fabrication processes has become a pivotal concern for industries aiming to enhance productivity and maintain competitive advantage. According to a recent report by the Manufacturing Institute, companies that have implemented advanced manufacturing technologies and optimized their production processes have seen productivity increases of up to 30%. This significant improvement underscores the necessity of adopting efficient strategies in part fabrication, as these processes are crucial not only for cost reduction but also for improving overall workflow and output quality.

Efficient part fabrication involves a comprehensive approach that includes the integration of automation, advanced materials, and data analytics. A study by Deloitte indicates that nearly 70% of manufacturers believe that increasing their investment in smart manufacturing is critical for sustaining their growth in the coming years. By focusing on key factors such as process standardization, waste reduction, and workflow optimization, companies can significantly shorten lead times and enhance operational efficiencies. The need for optimization in part fabrication is further amplified by the rising demand for customized solutions, which require manufacturers to be more agile and responsive to market changes.

Ultimately, adopting a strategic framework for optimizing part fabrication processes can empower organizations to thrive in a competitive marketplace. By addressing inefficiencies and leveraging modern technologies, manufacturers can not only boost their productivity but also ensure sustainable growth, setting the stage for innovation and success in the future.

Understanding Key Metrics in Part Fabrication Efficiency

In the realm of part fabrication, optimizing production processes hinges on understanding key efficiency metrics. These metrics play a crucial role in identifying areas for improvement and measuring the effectiveness of implemented changes. One of the most significant metrics is cycle time, which measures the total time it takes to complete a part from start to finish. According to a report by the Boston Consulting Group, reducing cycle times by just 20% can lead to a 30% increase in overall productivity. By focusing on minimizing downtime and improving workflow, manufacturers can achieve substantial enhancements in their production efficiency.

Another critical metric is yield rate, reflecting the percentage of products produced that meet quality standards. A study published in the Journal of Manufacturing Science and Engineering indicated that even a slight increase in yield rates—by as little as 5%—can dramatically reduce waste and costs associated with rework and scrap. Implementing robust quality control measures and leveraging real-time data analytics can assist in identifying defects early, thereby improving yield and enhancing the overall robustness of the fabrication process.

Furthermore, tracking overall equipment effectiveness (OEE) provides insight into how well manufacturing equipment is performing. Increasing OEE by merely 10% can have a significant ripple effect, translating to higher throughput and reduced operational costs. Manufacturers are encouraged to regularly analyze OEE components, including availability, performance, and quality, to pinpoint inefficiencies and streamline their fabrication processes. By strategically focusing on these metrics, companies can not only boost productivity but also pave the way for industry leadership in part fabrication efficiency.

How to Efficiently Optimize Part Fabrication Processes for Better Productivity - Understanding Key Metrics in Part Fabrication Efficiency

| Metric | Description | Value | Target |

|---|---|---|---|

| Cycle Time | Total time to produce a part from start to finish | 35 minutes | 30 minutes |

| First Pass Yield | Percentage of products that pass quality inspection the first time | 92% | 95% |

| Equipment Utilization | Ratio of actual production time to available production time | 85% | 90% |

| Scrap Rate | Percentage of materials that were wasted during production | 4% | 2% |

| Labor Efficiency | Output per labor hour | 50 parts/hour | 60 parts/hour |

Analyzing Advanced Technologies in Fabrication Processes

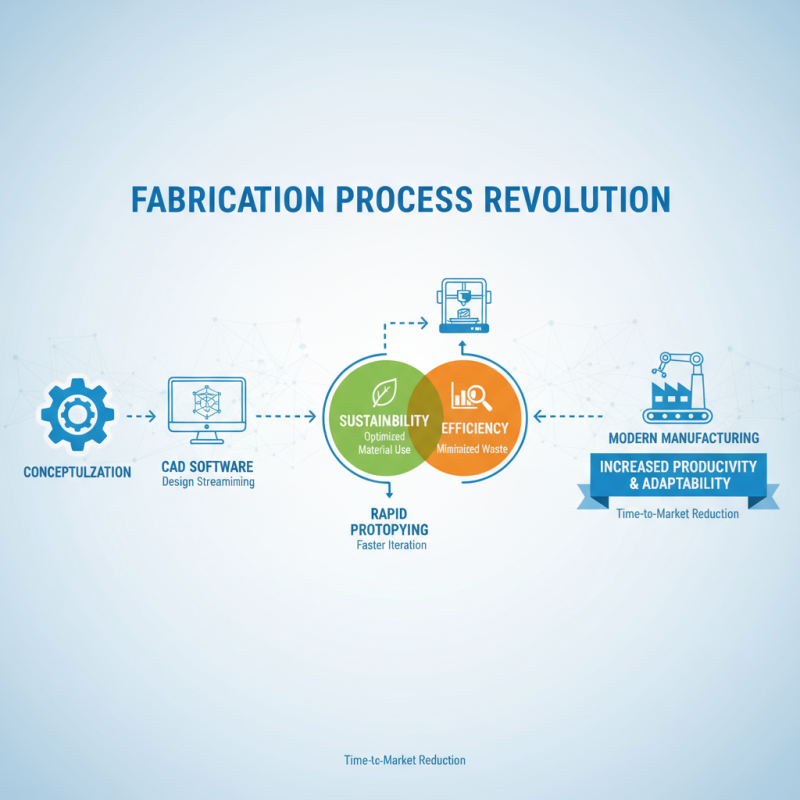

The advancement of technologies in fabrication processes has revolutionized the manufacturing landscape, enabling industries to enhance productivity and efficiency significantly. One of the critical technologies that have emerged is computer-aided design (CAD) software, which streamlines the design phase and allows for the rapid prototyping of complex components. By utilizing CAD, manufacturers can reduce the time from concept to production, making it easier to iterate designs and quickly adapt to changing requirements. The integration of simulation tools within CAD systems further aids in optimizing material usage and minimizing waste, which is crucial for sustainable production practices.

Another transformative technology is additive manufacturing, commonly known as 3D printing. This innovative approach allows for the creation of intricate parts that traditional subtractive methods may find challenging or impossible to achieve. By enabling the production of complex geometries with reduced material waste, additive manufacturing not only speeds up the fabrication process but also opens up new possibilities for customization and on-demand production. Additionally, advanced robotics and automation in fabrication processes increase operational efficiency by automating repetitive tasks and ensuring consistent quality control. As these technologies continue to evolve, they will play a pivotal role in shaping the future of manufacturing, driving productivity and reducing lead times across various industries.

Implementing Lean Manufacturing Principles for Optimization

Implementing lean manufacturing principles is crucial for optimizing part fabrication processes and enhancing productivity. Lean manufacturing focuses on minimizing waste while maximizing value, which involves a systematic approach to identifying and eliminating non-value-added activities throughout the production cycle. By analyzing workflows and engaging stakeholders in continuous improvement efforts, organizations can streamline operations, reduce lead times, and improve overall efficiency.

One effective strategy is the adoption of Just-In-Time (JIT) production, which aligns inventory levels with actual production demands. This approach not only reduces the costs associated with excess inventory but also improves responsiveness to market changes. Furthermore, employing tools such as Value Stream Mapping helps teams visualize and assess their processes, making it easier to pinpoint bottlenecks and areas for improvement. By fostering a culture of continuous feedback and teamwork, companies can empower employees at all levels to contribute to process enhancements, ultimately driving productivity gains in part fabrication.

Integrating Automation in Part Fabrication for Enhanced Productivity

The integration of automation in part fabrication is a transformative approach that significantly enhances productivity across manufacturing operations. By implementing automated systems, companies can streamline their workflows, reduce manual intervention, and minimize errors associated with human operators. Technologies such as robotic arms, conveyor systems, and computer numerical control (CNC) machines enable a higher degree of precision and efficiency. These automated processes allow for quicker turnaround times, meeting customer demands with improved responsiveness while maintaining consistent quality.

Moreover, automated part fabrication facilitates data collection and analysis throughout the production process. This real-time monitoring enables manufacturers to identify bottlenecks, optimize cycle times, and implement predictive maintenance strategies, ultimately reducing downtime. Integrating automation not only increases throughput but also allows for greater flexibility in production, accommodating changing designs and specifications with ease.

By optimizing part fabrication processes through automation, businesses can secure a competitive edge in the rapidly evolving manufacturing landscape, ensuring that they meet the challenges of modern production demands effectively.

Evaluating Supply Chain Impact on Fabrication Performance

The efficiency of part fabrication processes heavily relies on the intricacies of the supply chain. Research indicates that optimizing supply chain management can result in a production efficiency increase of up to 30%. For example, effective demand forecasting and inventory management can help manufacturers avoid delays that arise from shortages. According to a report from the Institute for Supply Management, firms that implement integrated supply chain strategies have reported an average improvement in operational performance metrics by 25%. This shows a direct correlation between supply chain optimization and fabrication productivity.

Evaluating the supply chain impact on fabrication performance also requires understanding the flow of materials and information. A streamlined supply chain enhances the responsiveness of fabrication processes, reducing lead times significantly. A study by the Supply Chain Management Review found that companies recognizing the importance of collaboration with suppliers can reduce fabrication times by as much as 20%. By adopting advanced technologies such as real-time data analytics and automation, businesses can not only enhance visibility across the supply chain but also facilitate a more agile production environment. This, in turn, fosters better decision-making, enabling manufacturers to respond swiftly to market demands while maintaining high-quality standards.

Optimizing Part Fabrication Processes for Better Productivity

Related Posts

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

2025 Top Steel Beam Fabrication Techniques for Modern Construction

-

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know

-

Top 10 Custom Stainless Fabrication Techniques for Your Next Project

-

What is Stainless Fabrication Its Process Benefits and Applications

-

10 Essential Tips for Successful Online Fabrication Projects