Projects

10 Essential Tips for Successful Online Fabrication Projects

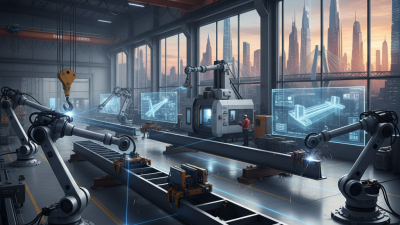

In the rapidly evolving world of online fabrication, professionals are constantly seeking ways to enhance their projects and streamline processes. As the industry grows, understanding the nuances of this dynamic field becomes essential for success. Bob Smith, a leading expert in online fabrication and founder of Fabrication Innovators, aptly noted, “Embracing technology in online fabrication is not just about tools; it’s about redefining creativity and efficiency in how we make things.”

The shift towards digital solutions in the fabrication sector has opened up new possibilities for creators, engineers, and makers alike. The increased accessibility of sophisticated software and machinery allows individuals and teams to bring their ideas to life with unprecedented ease. However, to navigate this complex landscape effectively, several key strategies must be adopted. From optimizing design processes to understanding material properties, the application of best practices can significantly influence the outcome of any online fabrication project.

By leveraging these insights and focusing on essential aspects such as planning, collaboration, and resource management, practitioners can position themselves for success in the competitive realm of online fabrication. The following tips encapsulate vital approaches that will empower creators to harness the full potential of this innovative industry.

Understanding the Basics of Online Fabrication Projects

Online fabrication projects have become increasingly popular due to advancements in technology and the accessibility of various tools. Understanding the basics of online fabrication is crucial for anyone looking to embark on these projects. At its core, online fabrication refers to the process of designing and creating objects using digital tools and platforms. This can encompass everything from 3D printing to laser cutting, allowing creators to transform digital designs into tangible products.

To begin with, it is important to familiarize yourself with the digital design software that is commonly used in fabrication projects. Tools like CAD (Computer-Aided Design) programs enable you to create precise models that can be translated into physical objects. Once you have a design, understanding the specifications of the material you plan to use is essential. Different materials may require unique settings and techniques, impacting the final outcome of your project. Additionally, learning how to navigate online fabrication services, which often involve uploading your designs and selecting materials for production, is key to ensuring a smooth creation process. By grasping these fundamental aspects, you can significantly enhance your chances of success in online fabrication endeavors.

10 Essential Tips for Successful Online Fabrication Projects

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Define Clear Objectives | Focused project direction |

| 2 | Research Materials | Informed material choices |

| 3 | Utilize CAD Software | Accurate design representation |

| 4 | Choose the Right Fabrication Method | Optimized production efficiency |

| 5 | Plan for Iterations | Improved final product |

| 6 | Communicate with Suppliers | Clear expectations and timelines |

| 7 | Test Prototypes | Identify design flaws early |

| 8 | Monitor Progress | Stay on track and on budget |

| 9 | Document Everything | Future reference and learning |

| 10 | Solicit Feedback | Continuous improvement |

Selecting the Right Tools and Materials for Your Project

When embarking on online fabrication projects, selecting the right tools and materials is pivotal to ensuring success. According to a survey conducted by the Fabrication Lab Network, 72% of respondents stated that the quality of materials directly impacted their project's outcome. Therefore, understanding the specific requirements of your project can guide you in making informed choices that align with your goals.

One essential tip is to evaluate the properties of various materials. For instance, when working with polymers, consider factors such as tensile strength, flexibility, and thermal resistance. The American Society for Testing and Materials (ASTM) states that improper material selection can lead to project failures, highlighting the need for thorough research. Additionally, choosing tools that match your material requirements is crucial. Using the right type of cutter or printer can significantly enhance the quality and precision of your work.

Furthermore, always keep a checklist of tools that are suitable for your chosen materials. This can include 3D printers capable of handling different filament types, laser cutters with adjustable settings for varying thicknesses, or CNC machines designed for specific substrates. According to a report from the International Federation of Robotics, approximately 70% of successful projects utilized properly calibrated equipment tailored to their materials. Therefore, ensure that you are well-equipped with the necessary tools to maximize your project's effectiveness.

Step-by-Step Planning and Design Process for Fabrication

When embarking on an online fabrication project, the planning and design process is crucial to ensure success. First, define the project goals clearly. This involves specifying the desired outcome, materials needed, and the intended use of the fabricated item.

Creating detailed sketches or 3D models can help visualize the end product and serve as a reference throughout the process. Utilizing software for design can also enhance precision and allow for adjustments before any physical fabrication begins.

Next, break down the project into manageable steps. This includes selecting the right fabrication techniques, determining the necessary tools, and establishing a timeline for each phase of the project. Researching available resources and platforms that offer fabrication services can aid in selecting the most suitable methods for your project requirements.

By systematically approaching the design and planning stages, you can minimize errors and streamline the workflow, ensuring your online fabrication project is successful from the outset.

Common Challenges and Solutions in Online Fabrication

When tackling online fabrication projects, several common challenges can emerge that require careful consideration and proactive solutions. One prevalent issue is miscommunication between the project creator and the fabricators. Often, project specifications can be misunderstood due to vague descriptions or technical jargon. To mitigate this, it is crucial to provide detailed documentation, including clear sketches or CAD designs, alongside written instructions. Engaging in open communication channels with the fabricators can also help ensure that everyone is aligned on the project objectives and requirements.

Another significant challenge is the inconsistency in material quality and fabrication standards. When sourcing materials from various online suppliers, discrepancies can arise that affect the final product. To address this, it is essential to conduct thorough research on materials beforehand and select suppliers who are known for their quality and reliability. Establishing relationships with trusted suppliers and requesting samples before placing large orders can also help ensure that the materials meet the project’s specifications. Investing time upfront to tackle these challenges can lead to smoother execution of online fabrication projects and ultimately enhance the final outcomes.

Best Practices for Collaboration and Communication in Teams

Effective collaboration and communication are paramount to the success of any online fabrication project. In a digital workspace, where team members may be geographically distributed, establishing clear communication channels is essential. Regular updates through project management tools, video calls, and instant messaging can help maintain transparency. Setting up a structured timeline and defining roles within the team can also significantly enhance accountability. Encourage team members to share feedback openly and constructively; this fosters a culture of trust and innovation, ultimately leading to improved project outcomes.

Moreover, using collaborative tools designed for remote teamwork can streamline the fabrication process. Shared digital platforms for file storage and management ensure that all team members have access to the latest designs and updates, preventing confusion and miscommunication. It is crucial to establish guidelines for effective collaboration, outlining how decisions will be made and how conflicts will be resolved. Regular check-ins can help to monitor progress and address any challenges quickly. By fostering an environment that prioritizes communication and collaboration, teams can navigate the complexities of online fabrication projects more efficiently and effectively.

Related Posts

-

How to Get Started with Welding and Fabrication Techniques for Beginners

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

Top 10 Important Factors to Consider in Iron Fabrication Projects

-

10 Best Tube Fabrication Techniques for Optimal Performance

-

2025 Top Steel Beam Fabrication Techniques for Modern Construction

-

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know