Projects

Top 10 Important Factors to Consider in Iron Fabrication Projects

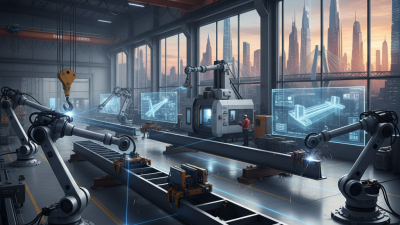

In the realm of construction and manufacturing, iron fabrication plays a pivotal role in shaping structures and components that are essential to various industries. As projects increasingly demand precision, durability, and aesthetic appeal, understanding the critical factors that influence iron fabrication becomes paramount. Whether you are embarking on a large-scale construction project or a bespoke fabrication endeavor, several elements can significantly impact the overall success and efficiency of the manufacturing process.

This article aims to outline the top ten important factors to consider in iron fabrication projects. From material selection to cutting techniques, each aspect can affect the project's outcome, timeline, and budget. It is essential for project managers, engineers, and fabricators to be well-versed in these considerations to ensure that the final products meet both functional and design requirements. By adhering to best practices and keeping these key factors in mind, stakeholders can optimize their iron fabrication efforts, resulting in high-quality outcomes that stand the test of time.

Key Considerations for Material Selection in Iron Fabrication

Material selection is a crucial element in the success of iron fabrication projects, as it directly impacts the performance and durability of the final product. When choosing materials, fabricators must consider factors such as mechanical properties, corrosion resistance, and thermal conductivity. Each type of iron or steel has its own specific characteristics, making it essential to understand how these elements will affect the intended application. For instance, higher carbon content can enhance strength but may reduce ductility, while alloying elements can contribute to improved resistance to wear and corrosion.

Additionally, the environment in which the fabricated product will be used plays a vital role in material selection. Products exposed to harsh outdoor conditions, chemical exposure, or extreme temperatures require materials that can withstand these challenges without degrading over time. A thorough analysis of the project requirements, including load-bearing capacities and environmental stressors, allows for a more informed selection process. Ultimately, aligning material characteristics with the functional demands of the project ensures longevity and efficiency, which are essential for successful iron fabrication.

Importance of Design Specifications in Iron Fabrication Projects

Design specifications play a crucial role in the success of iron fabrication projects. They serve as a roadmap that guides the entire fabrication process, ensuring that the end product meets both functional and aesthetic requirements. A well-defined design specification outlines the dimensions, material properties, and tolerances that are essential to achieving the desired outcomes. This clarity allows fabricators to accurately interpret the project goals, reducing the risk of errors and miscommunication that can arise during production.

Moreover, adhering to detailed design specifications is key to maintaining quality and consistency throughout the fabrication process. Specifications not only help in selecting the appropriate materials and techniques but also assist in establishing realistic timelines and budgets. By setting clear criteria for inspection and testing, stakeholders can ensure that each stage of the project meets the expected standards. Ultimately, the importance of design specifications cannot be overstated, as they are fundamental to the integrity and success of iron fabrication projects, influencing everything from safety to structural performance.

Top 10 Important Factors to Consider in Iron Fabrication Projects

Understanding Welding Techniques and Their Impact on Iron Structures

Welding techniques play a pivotal role in the integrity and durability of iron structures within fabrication projects. One key method, MIG (Metal Inert Gas) welding, is widely used due to its ability to deliver high-speed, high-quality joins while minimizing defects. According to a report from the American Welding Society, approximately 50% of the welding work done in the fabrication industry employs MIG methods. This process is particularly effective for thicker materials, enhancing the structural strength of iron components. Understanding the nuances of these techniques can significantly impact the overall success of a project.

Tip: When selecting a welding technique, consider the thickness of the materials and the desired strength of the weld. For instance, if working with thinner metals, TIG (Tungsten Inert Gas) welding might be a more suitable option, delivering precise and aesthetically pleasing results.

The importance of proper welding procedures cannot be overstated. Studies indicate that improper welding can lead to failures in structures, impacting safety and performance. A report by the National Institute of Standards and Technology highlights that nearly 70% of structural failures are attributed to issues related to welding quality. Therefore, investing in skilled labor and foreseeing potential challenges in the welding phase is vital in ensuring robust iron fabrications.

Tip: Regular training and certification for welders can dramatically improve the quality of work and reduce the risk of structural failures in projects.

Top 10 Important Factors to Consider in Iron Fabrication Projects - Understanding Welding Techniques and Their Impact on Iron Structures

| Factor | Description | Impact on Structure | Welding Technique |

|---|---|---|---|

| Material Quality | The grade and consistency of the iron used. | Directly affects the strength and durability of the structure. | MIG Welding |

| Welding Procedure | The specific methods and standards applied during welding. | Ensures uniformity and quality in welds. | TIG Welding |

| Design Specifications | Detailed drawings and measurements for fabrication. | Critical for ensuring structural integrity. | Arc Welding |

| Welder Certification | The qualifications of the personnel performing the welding. | Influences reliability and safety of welds. | Spot Welding |

| Environmental Conditions | Factors such as humidity and temperature during fabrication. | Affects the quality of the welds. | Submerged Arc Welding |

| Inspection and Testing | Process for assessing quality and integrity of welds. | Helps identify defects early on. | Non-Destructive Testing |

| Joint Design | The configuration of the metal pieces being joined. | Affects stress distribution and load-bearing capabilities. | Double-V Butt Joint |

| Heat Input | Amount of heat applied during welding. | Can influence the metallurgical properties of the iron. | Heat-Affected Zone Management |

| Post-Welding Treatment | Processes like annealing or surface treatment after welding. | Improves performance and corrosion resistance. | Heat Treatment |

Evaluating Costs and Budget Constraints in Iron Fabrication

When undertaking iron fabrication projects, evaluating costs and budget constraints is paramount for ensuring successful completion. A meticulous assessment of costs begins with understanding the materials required for fabrication. Different types of iron and steel can vary significantly in price, and selecting the most cost-effective option that meets performance requirements is essential. Additionally, labor costs must be considered, as skilled craftsmanship is vital to achieving high-quality results. Project managers should factor in the availability of skilled labor and potential overtime expenses to avoid budget overruns.

Another critical aspect of budgeting for iron fabrication projects is anticipating unforeseen expenses. In any construction or fabrication venture, unexpected challenges can arise, such as equipment malfunctions or design modifications. Allocating a contingency fund within the budget can help mitigate risks associated with these uncertainties. Furthermore, it's important to engage in detailed project planning and timeline estimation to avoid costly delays. A well-structured timeline allows for more accurate scheduling of labor and materials, thus maintaining financial control. By thoroughly evaluating costs and adhering to budget constraints, project stakeholders can enhance the overall efficiency and success of their iron fabrication endeavors.

Importance of Compliance with Industry Standards and Regulations

In iron fabrication projects, compliance with industry standards and regulations is crucial for ensuring both safety and quality. These standards often dictate the materials, techniques, and processes that must be followed during fabrication. Adhering to these guidelines not only safeguards workers but also enhances the structural integrity of the final product. Projects that neglect these regulations can face severe repercussions, including costly reworks, project delays, and potential legal liability.

To ensure compliance, it is essential to stay updated on the latest industry regulations and best practices. Regular training sessions for staff can significantly enhance awareness and understanding of these standards. Furthermore, integrating a compliance checklist into your project management system can streamline operations and mitigate risks.

Tips for achieving compliance include conducting regular audits of your fabrication processes to ensure adherence to industry standards. Additionally, fostering open communication with regulatory bodies can provide clarity and assist in navigating complex requirements. Staying proactive about compliance not only minimizes risks but also builds trust with clients and stakeholders, ultimately leading to improved project outcomes.

Related Posts

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

How to Master Welding and Fabrication Techniques for Successful Projects

-

How to Get Started with Welding and Fabrication Techniques for Beginners

-

2025 Top Steel Beam Fabrication Techniques for Modern Construction

-

10 Best Tube Fabrication Techniques for Optimal Performance

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget