Projects

How to Master Welding and Fabrication Techniques for Successful Projects

In the world of construction and manufacturing, mastering welding and fabrication techniques is essential for anyone looking to excel in their projects. Welding and fabrication serve as the backbone of countless industries, from automobile manufacturing to custom metalwork, allowing fabricators to create durable, high-quality products that stand the test of time. This introduction will guide you through the critical aspects of becoming proficient in these techniques, providing a solid foundation for successful project execution.

The journey to mastering welding and fabrication begins with understanding the various types of welding processes, including MIG, TIG, and stick welding. Each method has its own set of applications, advantages, and challenges, making it vital for both beginners and experienced welders to comprehend their nuances. Additionally, exploring the principles of metal fabrication, such as cutting, shaping, and assembling materials, is crucial for achieving desirable results in any project. By delving into these core areas, aspiring professionals can develop a comprehensive skill set that enhances their craftsmanship and boosts their confidence.

Ultimately, mastering welding and fabrication techniques not only empowers individuals to tackle complex projects but also fosters a sense of creativity and innovation. With the right tools, practice, and knowledge, anyone can bring their ideas to life, contributing to a more skilled and capable workforce in an ever-evolving industrial landscape. Whether you are a hobbyist or a seasoned professional, embracing these techniques will undoubtedly lead to successful and fulfilling projects.

Understanding the Fundamentals of Welding Processes: MIG, TIG, and Stick Techniques

Welding is a vital skill in the fabrication industry, and understanding the various processes is essential for effective execution. MIG (Metal Inert Gas) welding is one of the most common techniques, lauded for its versatility and ease of use. It involves feeding a continuous solid wire electrode through a welding gun and into the weld pool, which is shielded by an inert gas. This process is ideal for beginners as it allows for faster welding speeds and cleaner results, making it suitable for both thin and thick materials.

TIG (Tungsten Inert Gas) welding offers a different approach, utilizing a non-consumable tungsten electrode to produce the weld. This technique requires a greater level of skill and precision but results in high-quality, clean welds. TIG welding is preferable for applications that demand strong, aesthetically pleasing joints in materials such as stainless steel and aluminum. On the other hand, Stick welding, or Shielded Metal Arc Welding (SMAW), is a traditional method, known for its effectiveness in outdoor environments. It involves a consumable electrode coated in flux, which not only provides filler material but also generates a shielding gas when burned, protecting the weld area from contamination. Each of these techniques has unique advantages and is chosen based on the specific demands of a project, emphasizing the importance of mastering these fundamental welding processes for successful fabrication.

How to Master Welding and Fabrication Techniques for Successful Projects

| Welding Technique | Material Compatibility | Key Advantages | Typical Applications |

|---|---|---|---|

| MIG Welding | Steel, Stainless Steel, Aluminum | Fast and versatile; Easy to learn | Automotive, Fabrication, Repair |

| TIG Welding | Steel, Stainless Steel, Aluminum, Copper | High precision and control; Clean welds | Aerospace, Artistic Structures, Thin Materials |

| Stick Welding | Steel, Cast Iron | Works well outdoors; Less equipment required | Construction, Heavy Fabrication |

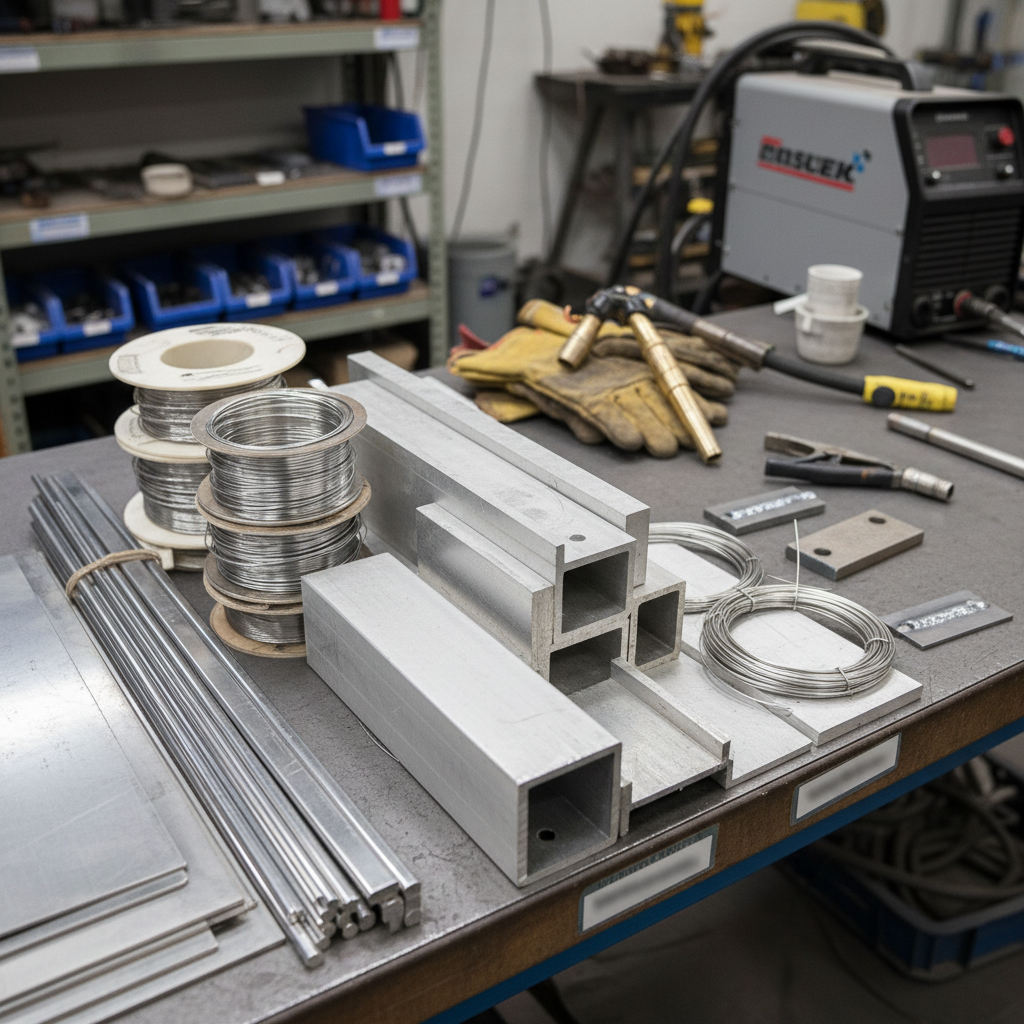

Selecting the Right Materials: Choosing Alloys and Filler Metals for Your Fabrication Projects

Selecting the right materials is crucial for achieving successful outcomes in welding and fabrication projects. Different alloys and filler metals have unique properties that can significantly affect the strength, durability, and overall performance of the final product. For instance, stainless steel is often favored for its corrosion resistance, making it an ideal choice for projects exposed to harsh environments. On the other hand, aluminum alloys are lightweight and beneficial for applications where weight is a critical factor.

When choosing filler metals, compatibility with the base material is essential. For example, when welding mild steel, the use of ER70S-6 filler metal is a standard practice due to its excellent properties and ease of use. However, for more specialized applications, such as joining dissimilar metals or working with high-strength steels, it is vital to select suitable filler metals that can provide optimal mechanical properties and defects-free joints. By thoroughly understanding the characteristics of available materials, fabricators can make informed decisions that enhance the quality and longevity of their projects.

Essential Tools and Equipment: Investing in the Best Gear for Quality Welding Results

When it comes to mastering welding and fabrication techniques, the quality of your tools and equipment plays a pivotal role in achieving exceptional results. According to a report by Grand View Research, the global welding equipment market size was valued at approximately $17 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth underscores the increasing importance of investing in high-quality gear to ensure the durability and efficiency of welding projects.

Selecting the right tools can dramatically enhance the precision and safety of your work. Essential equipment such as MIG and TIG welders, plasma cutters, and protective gear should not be compromised. The American Welding Society emphasizes that having the correct equipment not only improves the overall quality of welds but also influences the welder's technique and confidence. For example, using a high-quality MIG welder can lead to fewer defects and a smoother finish, which is crucial when taking on intricate fabrication projects. Investing in the best gear is not just about immediate results; it's also about building a foundation for successful and sustainable practices in the longer term.

Safety First: Implementing Best Practices to Prevent Common Welding Hazards

Welding is a highly skilled profession, but it also comes with inherent hazards. According to the U.S. Bureau of Labor Statistics, approximately 50,000 welding-related injuries occur annually, often due to inadequate safety practices. To mitigate risks, it is essential to implement best practices that prioritize safety. This includes thorough training on the operation of welding equipment and understanding the specific hazards associated with different welding processes. Proper protective gear, such as helmets, gloves, and flame-resistant clothing, forms the first line of defense against accidents.

Furthermore, maintaining a clean and well-organized workspace significantly reduces the likelihood of incidents. The American Welding Society reports that most welding injuries result from slips, trips, and falls. By ensuring that pathways are clear and that combustible materials are stored correctly, welders can create a safer working environment. Regular safety audits and the establishment of a culture that encourages reporting unsafe conditions are equally vital. Through vigilant adherence to these best practices, practitioners can not only protect themselves but also enhance the quality and efficiency of their welding projects.

Advanced Techniques: Exploring Automation and Robotics in Modern Welding Fabrication

The integration of automation and robotics in modern welding fabrication has revolutionized the industry, enhancing efficiency and precision in projects. Automation streamlines repetitive tasks, allowing skilled workers to focus on more intricate aspects of the fabrication process. By employing automated systems, organizations can significantly reduce production time and minimize human error, ensuring a consistently high-quality output. This shift not only boosts productivity but also lowers labor costs in the long run.

Robotics, on the other hand, offers unparalleled flexibility and adaptability in welding applications. Advanced robotic arms equipped with sophisticated sensors and intelligent software can execute complex welding patterns with remarkable accuracy. This technology enables manufacturers to tackle challenging geometries and diverse materials that would be difficult or impossible to handle manually. As the welding industry continues to embrace these advanced techniques, the potential for innovation and improved project outcomes expands, paving the way for more ambitious and high-quality fabrication endeavors.

Welding Techniques Adoption Over Time

This chart illustrates the adoption rate of traditional versus advanced welding techniques over a five-year period. The shift towards automation and robotics in modern welding fabrication is evident as the industry evolves.